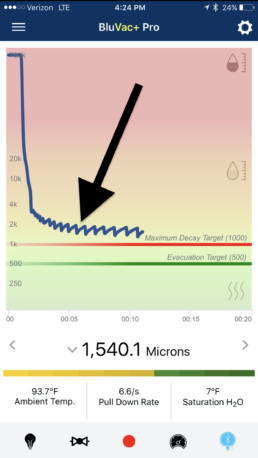

My BluVac is reading erratically

Ever wonder what those blue squiggle lines mean on your BluVac reports? Jim will explain what those readings mean and why you're getting them. We dive deep into the AccuTools core removal tools and explain the difference between ours and the competitors. It's a highly informative video that could save you time on the job site.

Why does the micron level increase after the valve is closed and the pump is turned off?

You will see leakage because the volume it's holding is so small. The gauge has such high sensitivity, you will see things you would not normally. The only way to alleviate this is to run the pump for a very long time, on the order of many hours or day, or adding heat. Check out the video at about 4 minutes in to hear more about it.

For a more in-depth understanding: All solid materials have an affinity of water vapor. This water vapor "adsorbs" onto the internal metal surfaces of the volume being evacuated. Just like liquid water, the adsorbed water has a vapor pressure. The vapor pressure is dependent upon the number of layers of water molecules adhered to the surface, and the temperature of the surface. The water "desorbs" when the pressure in the volume is dropped below the vapor pressure, but only very slowly - especially at room temperature. When the pump is blanked off, the water continues to desorb, very quickly raising the pressure of the small internal volume. Click here to learn more about water vapor and the properties of moisture.

For gauge confirmation, we recommend...

- Attach the gauge directly to the vacuum pump. A good two-stage pump with fresh, dry oil will pull the gauge to below 30 microns within about a minute or two. If this pressure can be achieved, it is indicative that both the gauge and pump are working properly. A leaking gauge would not allow the pressure to be pulled so deep.

- Attach the gauge to a backing volume (clean recovery tank) with a quality Valve Core Removal Tool. Pull the vacuum deep for at least one hour and blank off the Core Tool. After an initial rise, the pressure should level out over a short period of time - indicating a leak free gauge, Core Tool and connections. A pressure that continues to rise linearly (a straight line up) indicates a leak somewhere in the setup - but not likely the gauge itself.

Interested in purchasing a Core Removal Tool?

Our New Adapters

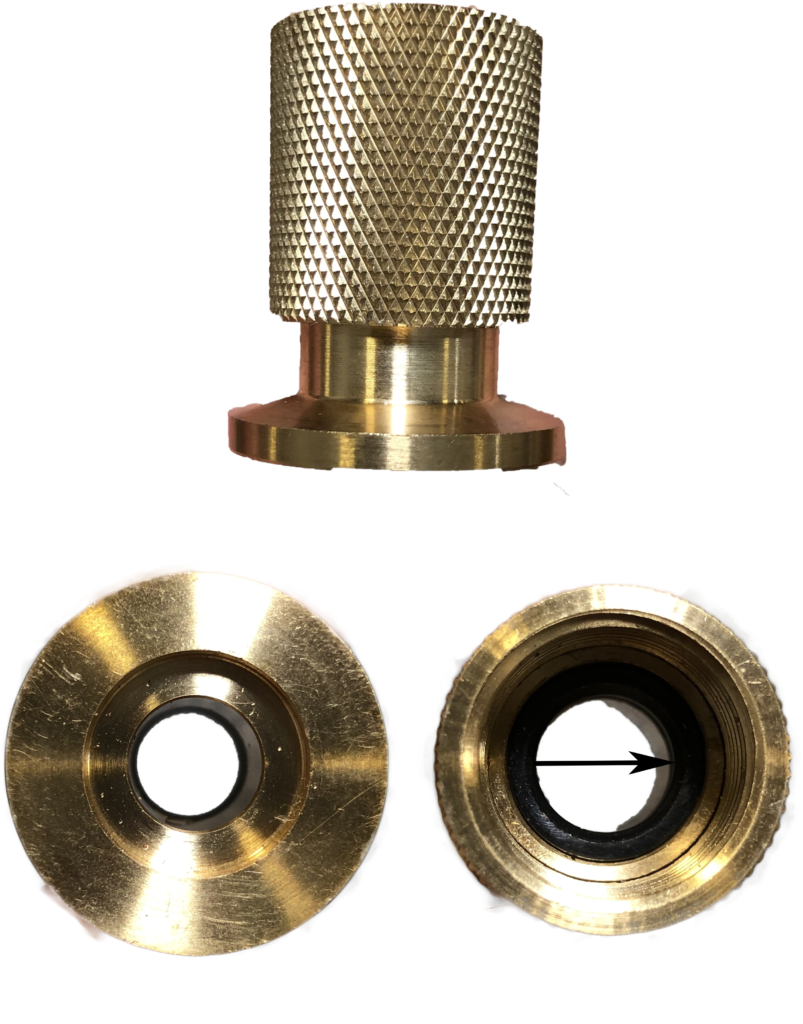

Not sure if you noticed, but we've improved our adapters!

If you've purchased a kit after March 1, 2020 you likely have the new adapters. Here's what to look for in the new editions.

New 1/2 Inch Adapter

Old 1/2 Inch Adapter

New 1/4 inch Adapter

Old 1/4 inch Adapter

New Right Angle Adapter

Old Right Angle Adapter

So let's talk facts. If you look closely at the images you will notice the port center is a bit bigger on the newer adapters. You may be thinking, "The wider ports will have faster flow than the older ones." The larger port size does NOT affect the speed of the evacuation. If you need more explanation on why port size doesn't matter, take a look at this video. The port size only matters until 20,000 microns is hit, which is milliseconds worth of time in a normal vacuum.

So you're probably asking yourself "Well why did they change their adapters then?" We made these changes for a few reasons; The newer adapters are a bit more compact, they look better and they have fewer brazing points.

If you're looking for replacement gaskets

Which gasket to purchase?

AccuTools changed the brass adapters in late February 2020; it hit the shelves in early March. The differences between the parts is the older gasket is raised above the lip of the adapter. In the new adapters, the gaskets fit well within the fitting.

Part Number for older adapters SA10868

Part Number for new adapters SA10868-1